Haug Blog - Informs about the latest developments

The journey of a cable

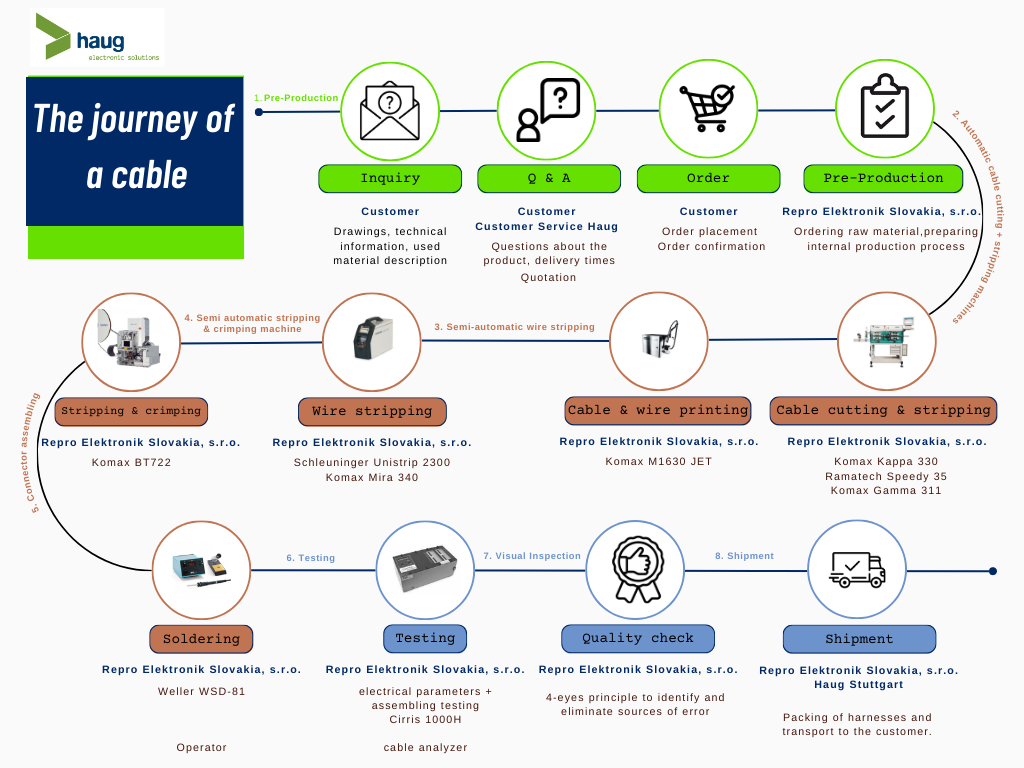

OUR SELF-PRODUCED CABLES HAVE A LONG JOURNEY BEHIND THEM. THEY CROSS COUNTRY BORDERS AND HAVE SEEN NUMEROUS DIFFERENT MACHINES ON THEIR WAY. ONLY THEN WILL YOU REACH YOUR GOAL AND FINALLY MAY GO INTO OUR CUSTOMERS' APPLICATION AND PURSUE YOUR ACTUAL TASK.

We manufacture customer-specific cable assemblies for ready-to-connect connectors, cables, strands, cable bundles and entire cable harnesses with plugs, contacts or wire-end ferrules. Various connector solutions can be used in our processing in order to offer our customers the best possible flexibility. Our projects are independent of quantities. In order to keep delivery routes short, we manufacture "Made in Europe".

What is a cable?

A cable is generally referred to as a bundle of isolated individual cores or strands. This bundle in turn is then also covered with an insulating material to hold it together. To protect signal cables from radio interference, for example, since these measured values can falsify, some cables are still wrapped in wire mesh.

WHAT TYPES OF CABLES ARE THERE?

The classic types of cables are round cables. They are best laid and processed. They are also ideal for laying in cable glands. Such cable glands can be found where there is a wall opening, but this must be prevented from further ingress of dirt and water, such as in a terminal box.

Other cable types are e.g. flat cables. Here the individual wires are attached next to each other.

Such cables are used, for example, for mechanical movements such as elevators or trolleys, as they react more flexibly to movement than round cables.

Facts and Figures

- Founded in September 2001

- Start of production in April 2002

- More than 20 years of wiring harness manufacturing experience

- Current number of employees: 100

- Turnover in 2022: €6,390,000

- Size: 5,619 m²

ADVANTAGES OF HAUG CABLE ASSEMBLY:

Personal contact

At Haug you always have a direct contact person. The sales employee records the requirements and clarifies the framework conditions, the order manager takes over the processing. And if all else fails, there is a product manager for tricky topics.

Individuality of the cable

Thanks to our many modern machines, we are also able to implement complex cable requirements. In advance, we check carefully whether production is possible or not. We only take on work that we can do, because this is the only way we can produce a 100% perfect cable for the customer.

Delivery reliability

Thanks to our more than 20 years of experience in the production of cables and the well-established processes between sales, purchasing, production and shipping, we can ensure flawless delivery on the agreed terms. If there are any delays, we will inform you proactively.

Quality check

With a detailed production plan of your cable, we guarantee a structured processing of the request. After production, there are machine and visual checks that identify and eliminate possible errors.

Costs

We are happy to pass on our good purchasing conditions, which we have thanks to large purchase quantities, to you. We produce large quantities at fair costs. You can also benefit from this.

English

English  Deutsch

Deutsch